Contact us:

Dr. Zifei Liu

Assistant Professor

Biological & Agricultural Engineering

Kansas State University

043 Seaton Hall

Manhattan, KS 66506

Email: Zifeiliu@ksu.edu

Phone: 785-532-3587

Fax: 785-532-5825

Timing of prescribed burning activities

Frequency of burns

The most obvious method of smoke reduction is a non-burning alternative or reducing the frequency of burns. Although there is scientific consensus supporting the need for prescribed fires in native grasslands, there is debate regarding optimal frequency of burns. The frequency of burns usually varies from yearly to every third year, depending on the type of livestock operation (e.g., cow-calf, season-long yearlings and short season stockers), burning constraints, and weather/grass growth conditions. Frequent burning increases number of acres burned each year, but it may also result in more rapid and complete burn due to fewer build-up of woody vegetation. Patch-burn grazing (PBG) has been suggested as a way to promote biological diversity in the Flint Hills and has potential to reduce smoke emissions. Typically, one-third of a PBG pasture is burned each year on a rotational basis.

Timing of prescribed burning activities

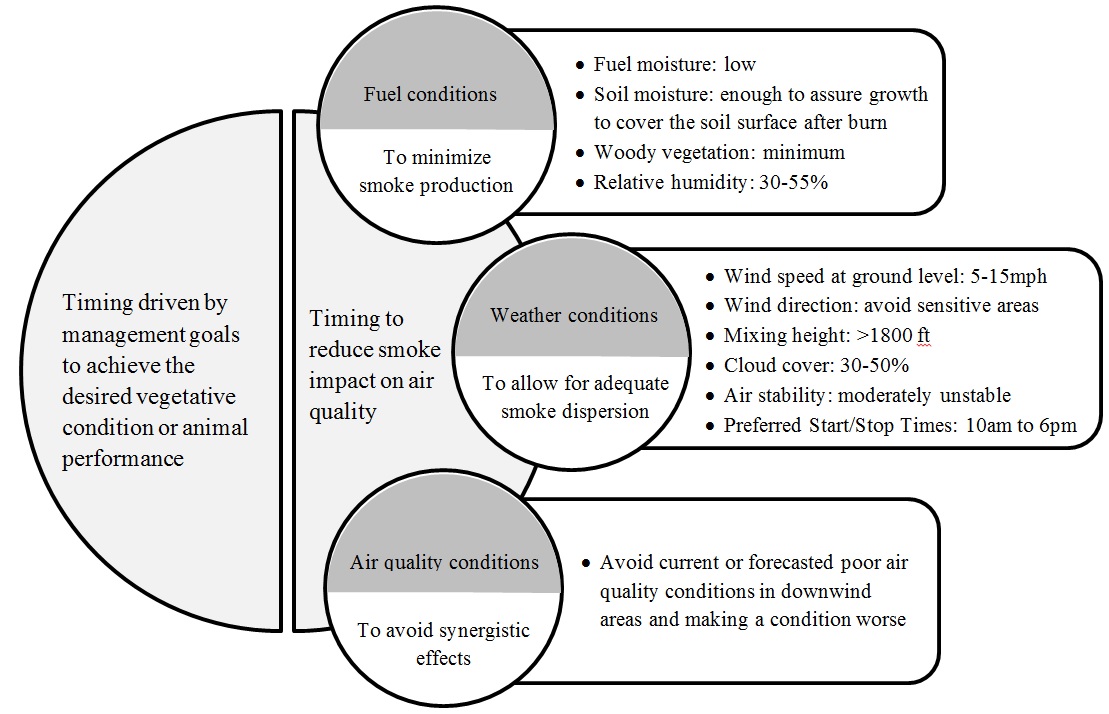

Timing of prescribed burning activities is usually driven by a specific management goal related to the desired vegetative condition or animal performance. Timing of a burn can also significantly impact the production and dispersion of smoke. With air quality concerns, land managers should time their burn to ensure favorable fuel conditions and weather conditions to reduce smoke impact. A checklist for land managers to consider on timing of burns is presented in the following Figure. Different times of the year provide different vegetative responses to prescribed fires. To stimulate warm season tall grasses, prescribed burn activities in the Flint Hills are generally scheduled during the month of April. Weather conditions and safety issues further limit number of days that are suitable for burning. Air quality is under greater pressure when too many burns occur and a large amount of smoke is released in to air during a short period of time. Therefore, the KDHE smoke management plan includes some restrictions on non-essential burning in April.

Fuel conditions that minimize smoke production

Efficient fuel combustion results in less smoke production. High fuel moisture reduces combustion efficiency and produces more smoke. This water vapor from fire can condense onto fine particulate matter and exacerbate the formation of haze. Grasses and forbs burn more efficiently than shrubs and woody species. Woody vegetation and denser canopy areas are often associated with smoldering conditions which produces more smoke. Reducing fuel loads through management practices like livestock grazing can reduce overall smoke emissions. The ideal fuel conditions are dry matter with little to no woody vegetation and adequate winds to complete combustion.

Weather conditions that allow for adequate smoke dispersion

Weather conditions such as wind and atmospheric stability influence the way smoke is dispersed. Weather conditions that allow for adequate smoke dispersion are desired at the day of burning to reduce smoke impact on air quality. Adequate wind speed help disperse a plume but very strong wind may also cause a plume to lay-down near the surface and inhibit vertical dispersion. Also, burning should occur when wind direction is safe and has minimal impacts on sensitive areas. Atmospheric stability refers to the atmosphere’s ability for the vertical motion which is affected by wind (which cause turbulence) and heating effects (which cause convection). In unstable conditions, the warmer lighter air at ground level rises and mixes with the cooler air in the upper atmosphere, therefore ground level pollution is readily dispersed. In contrast, a very stable condition occurs when temperature of air increases with height, which is referred to as “temperature inversion” because the warmer air above cooler air acts like a lid, suppressing vertical mixing. Burning under persistent “temperature inversion” is not recommended. Mixing height is a convenient term used to describe the potential for vertical mixing, which defines the height above the ground through which relatively vigorous mixing will take place. Ideal mixing heights for burning generally occur during the day after the sun has adequately heated the ground. The mixing heights tend to decrease as the sun goes down. Cloud cover can impact mixing heights because it prevents the sun from heating the ground which is needed to promote convection, but it also help limiting ozone formation due to reduction in photochemical reactions. Ideal burning conditions occur with cloud cover between 30-50%. Land managers can obtain information on weather conditions by accessing the Fire and Smoke Planning Resource website (www.ksfire.org) or the National Weather Service Fire Weather Forecast Website (www.srh.noaa.gov/ridge2/fire/).

Air quality conditions

When poor air quality conditions are observed or forecasted in areas that may be affected by fire smoke, a burn should be rescheduled to avoid making a condition worse. Poor air quality is usually associated with poor weather conditions that do not favor dispersion of air pollutants. However, on a day with suitable weather conditions for burning, too many burns may occur at the same time and burning should be planned and limited cooperatively so as not to overwhelm the ability of the atmosphere to disperse the smoke. Land managers can obtain air quality information from EPA’s AIRNOW website: (www.airnow.gov/).

(Reference: State of Kansas Flint Hills Smoke Management Plan. December, 2010)